Cable Bracing

The System

Gripple Seismic Cable Bracing Systems are specifically designed and engineered to brace and secure suspended nonstructural equipment (VAV boxes, fans, unit heaters, small in-line pumps, etc.) and components (HVAC duct, conduit/cable tray, and piping) within a building or structure to minimize damage from an earthquake or a seismic event.

Gripple Seismic Bracing systems are ideal for use on nonstructural components and equipment requiring seismic design, such as in essential facilities that are required for emergency operations in the aftermath of an earthquake.

Gripple Seismic Cable Bracing Systems offer the following advantages:

- Complete pre-engineered systems

- No field swaging of cables

- Up to 10 times faster to install

- No tools required

- Color coding allows easy field verification from the ground

- Suitable for new or retrofit installations

- Can be used in a variety of bracing configurations (transverse, longitudinal, 4-way)

- IAPMO approval (GS10, GS12, GS19, and GS 25 systems)

- SMACNA verified

- UL tested for NEBS GR 63 Core

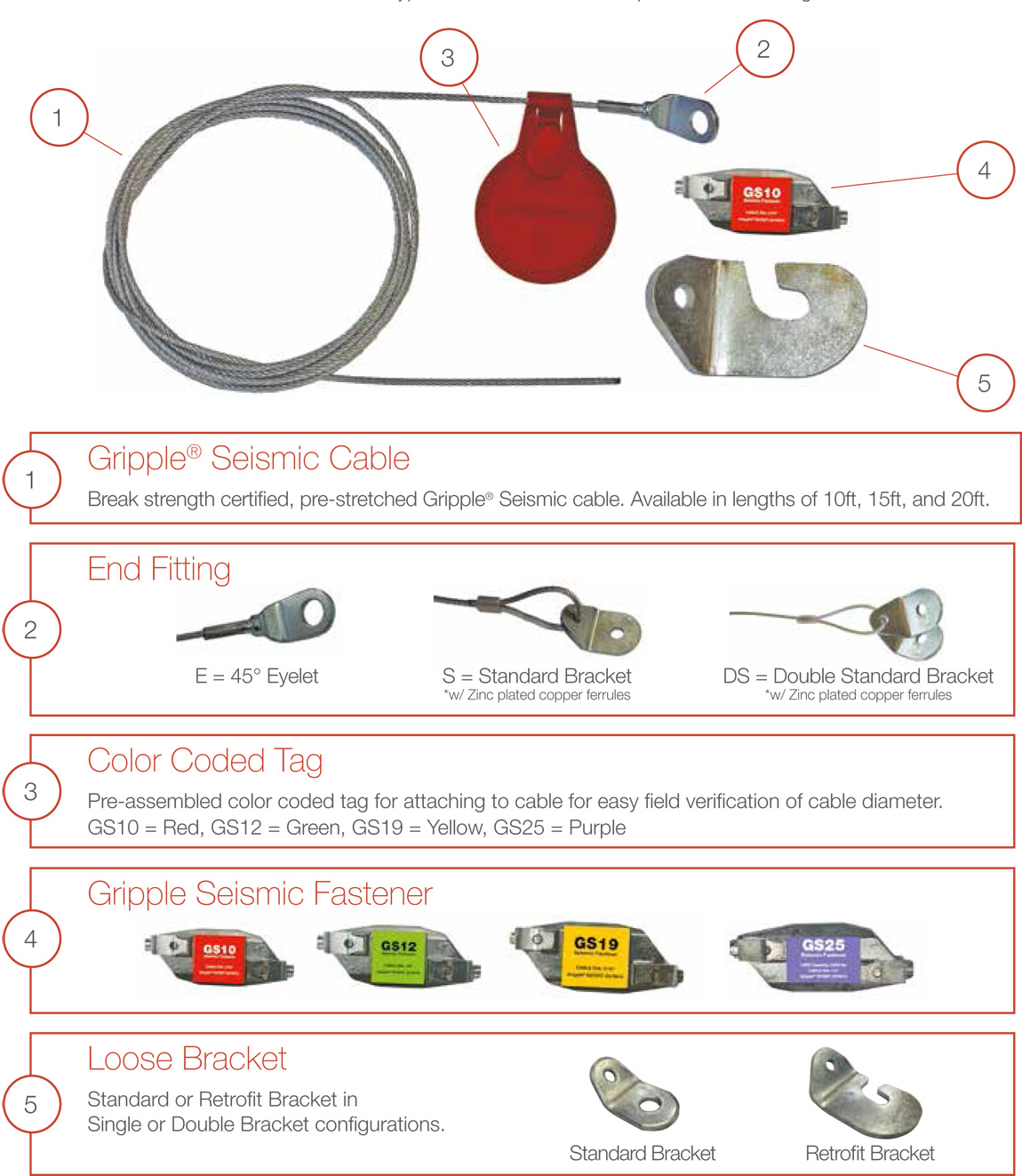

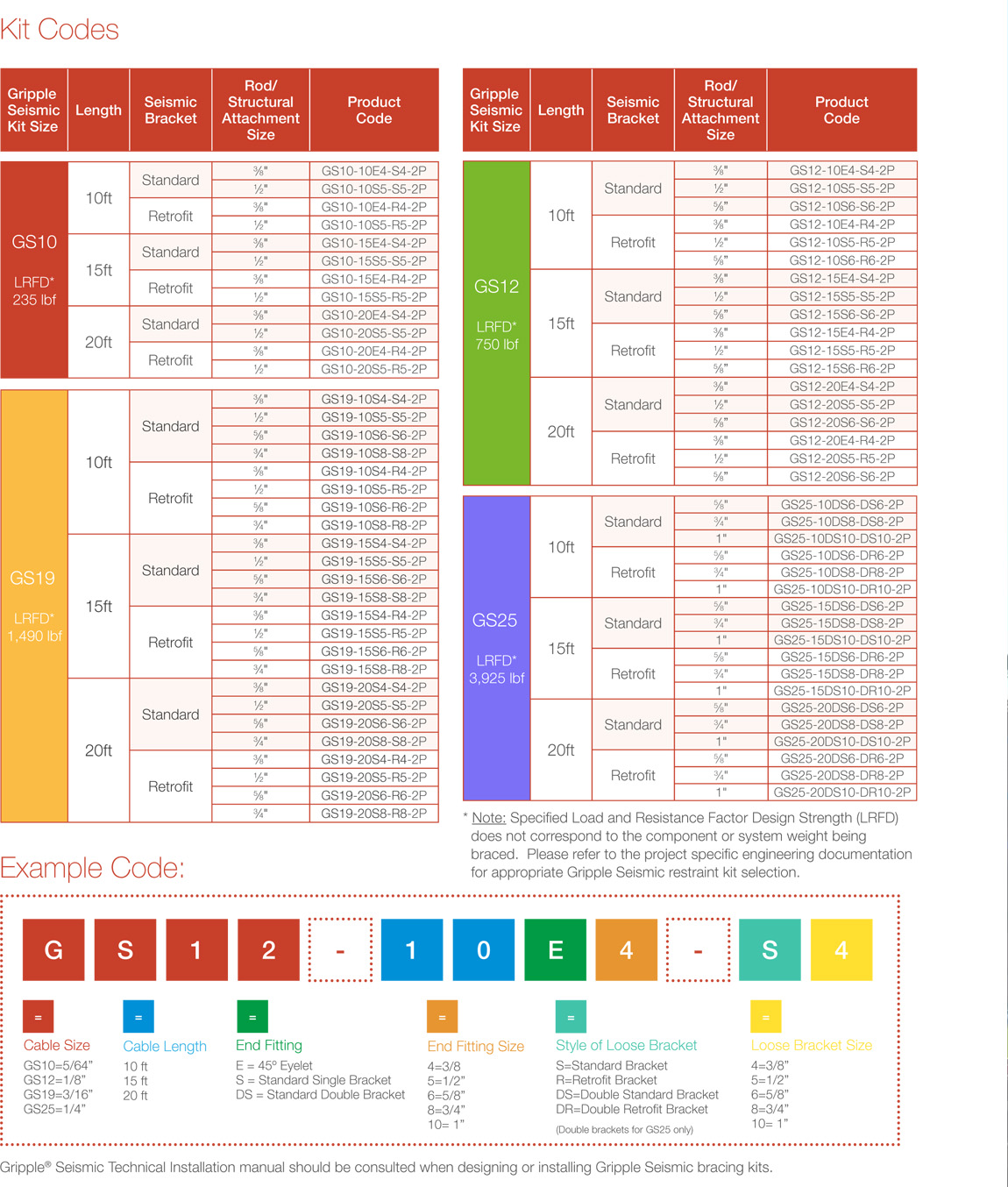

Complete bracing kits include a length of cable with pre-attached end fitting, color-coded tag, Gripple Seismic fastener, and standard or retrofit bracket. Four kit sizes are available:

* Note: Specified Load and Resistance Factor Design Strength (LRFD) does not correspond to the component or system weight being braced. Please refer to the project specific engineering documentation for appropriate Gripple Seismic restraint kit selection.

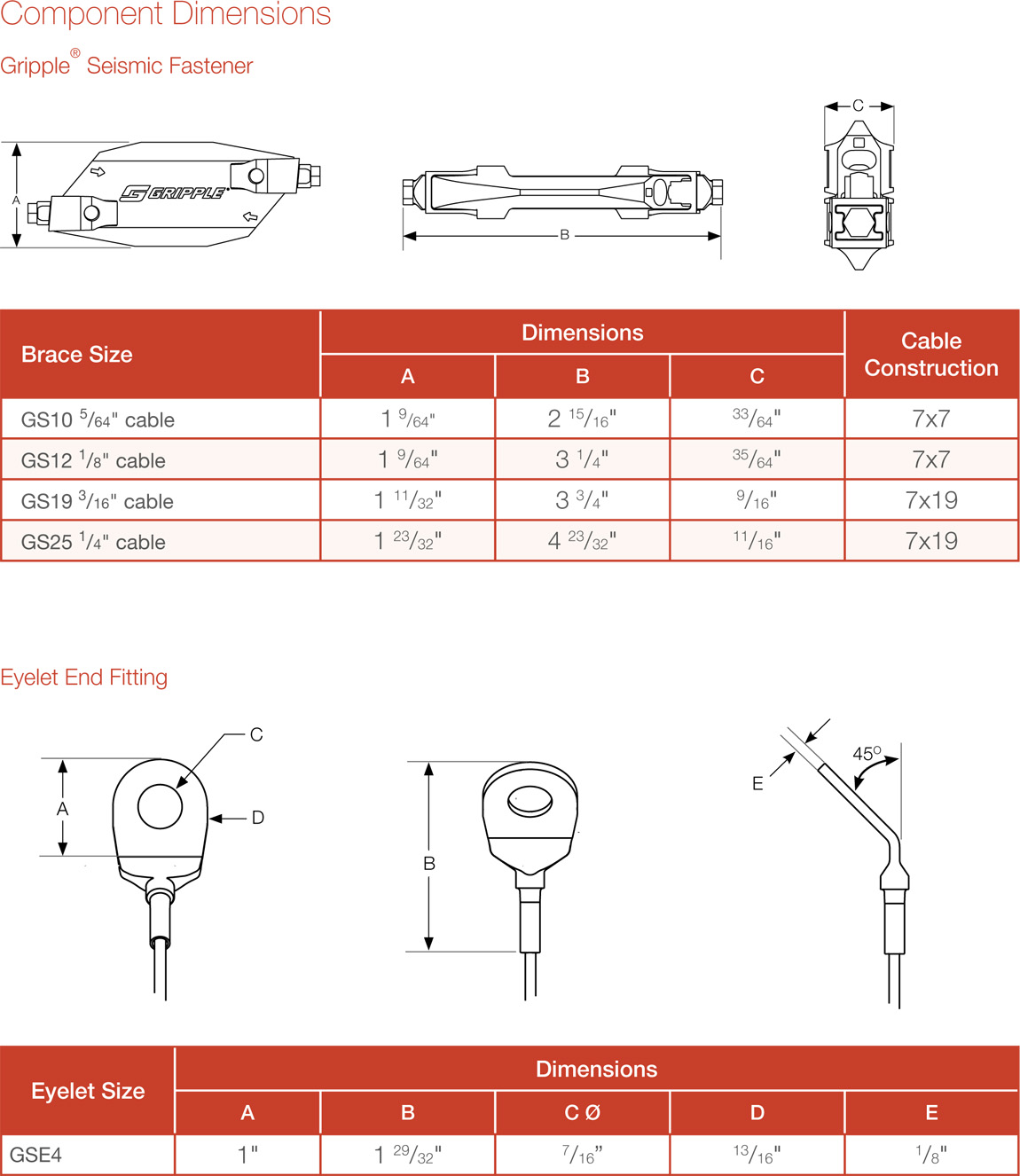

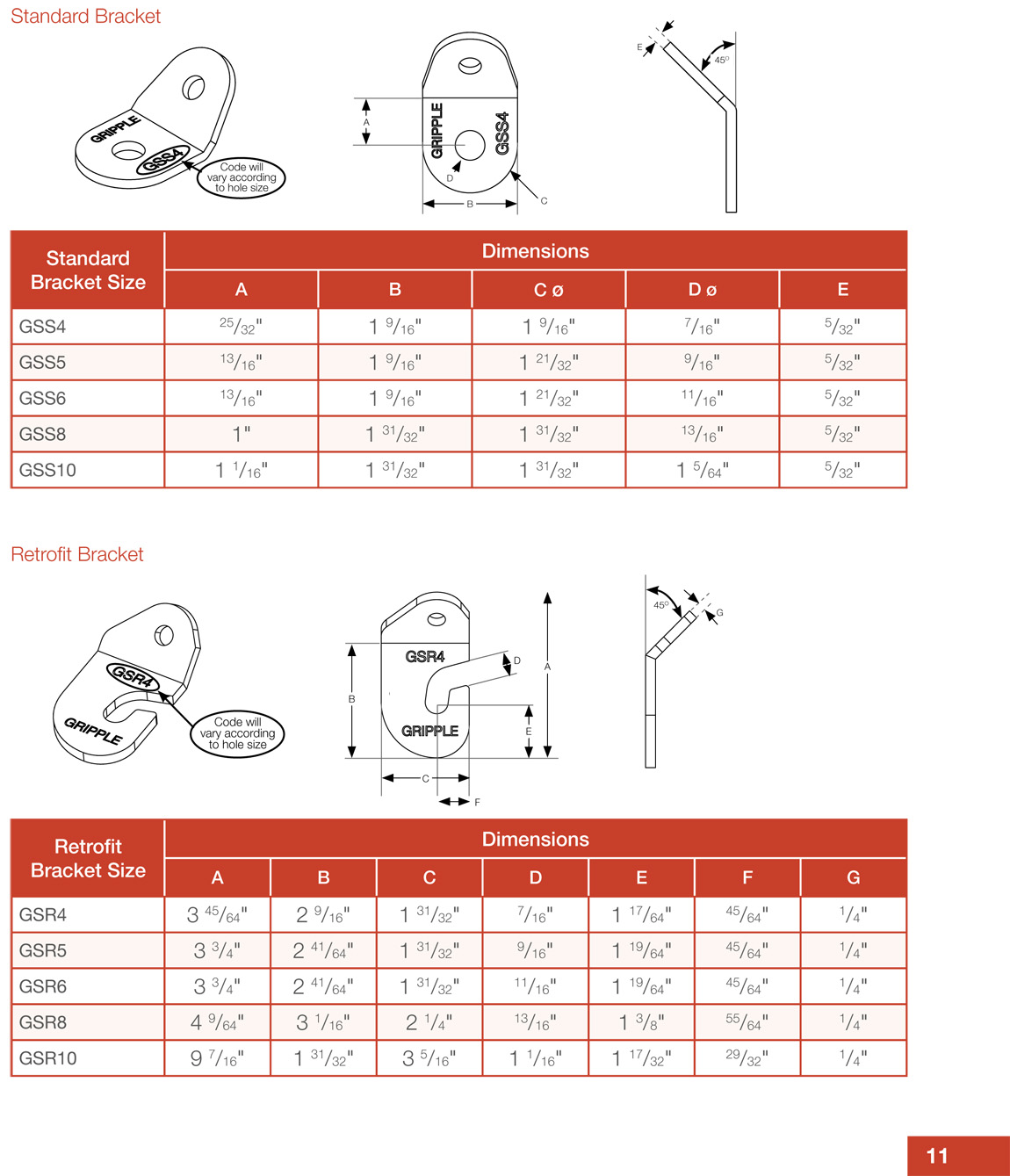

Components

There are four Gripple® Seismic cable bracing kit sizes available, each with its own Load and Resistance Factor Design (LRFD), selection of cable lengths, pre-attached end fittings, and bracket. As part of our Engineering services, Gripple will ensure that the bracing meets the seismic design requirements of the nonstructural components as related to weight loads and types of connections. Complete Cable Bracing Kits include the following components: